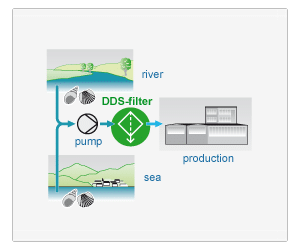

Mussels and mussel larvae are an increasing danger for the industry. Once, the mussels or their larvae are in your system, they can spawn unhindered and clog the whole piping system. DANGO & DIENENTHAL developed a unique MUSSEL STOP system, which reliably protects your plant components from mussel infestation and minimises shutdowns and maintenance costs.

Problem case: Zebra mussel

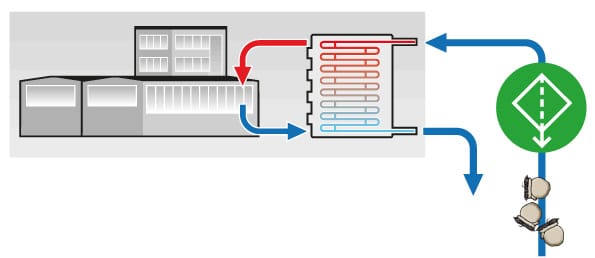

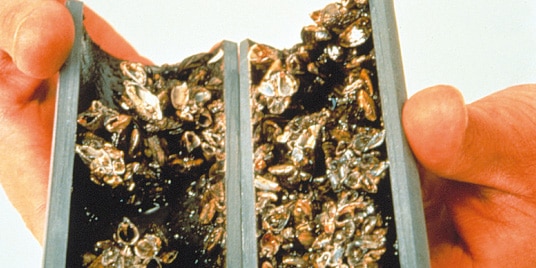

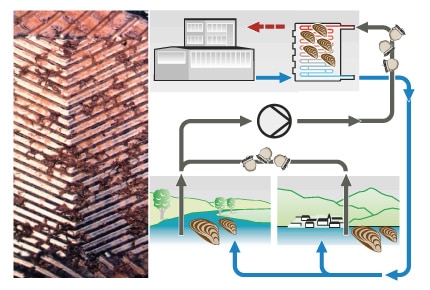

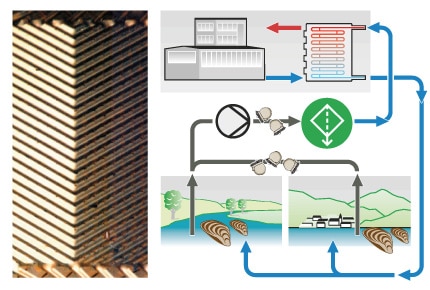

For many years, the zebra mussel (lat.: Dreissena polymorpha) has been spreading to countless rivers and lakes throughout the globe. For the industry, this rapid increase means damages in the millions of dollars. With this infestation in our lakes and rivers, the zebra mussels are transported into the cooling circuits of industrial plants, where they interfere with the proper function of plate and tube heat exchangers.

In most cases, the mussels and their larvae are killed using chemicals and then flushed out of the pipes afterwards. Unfortunately, the chemical treatment method has environmental issues and is also very expensive. A very effective way of fighting the mussels even in their early larval stage is to purchase mechanical filter units with

MUSSEL STOP system by DANGO & DIENENTHAL.

Effective problem solution with MUSSEL STOP

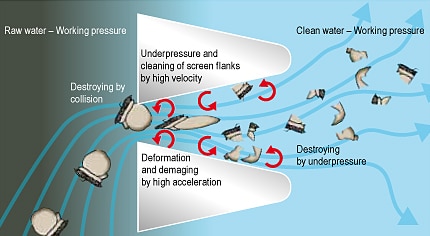

By operating a MUSSEL STOP system by Dango & Dienenthal, the mussel infestation of cooling components in all industries can be avoided effectively. This effectiveness is a result of the unique slot design with a filter fineness of approx. 300 µm in Filterautomats and JET Filters including MUSSEL STOP. The optimum relation of filter surface and flow rate allows for very high filtration velocities, greatly accelerating the mussel larvae in combination with the special slot geometry. At that point, strong caviation forces are destroying the larvae, as they pass through the filter element. Appropriate tests have shown that the caviation force should be at least 1,000 g to kill the mussel larvae effectively. Filterautomats and JET Filters with MUSSEL STOP by DANGO & DIENENTHAL do meet these parameters.